Our vertical conveyor systems are not to be confused with elevator, spiral or reciprocating systems. No—our unique take on a vertical conveyor turns a horizontal conveyor on its side, positioning the conveyor belt surface vertically. This unique belt-positioning brings with it a number of advantages. In this blog, we’ll explore the top 5 benefits of vertical conveyors and share some design considerations.

Benefit 1: Increased Productivity

By using both sides of the conveyor belt, the output is doubled. This is especially helpful when:

By using both sides of the conveyor belt, the output is doubled. This is especially helpful when:

- Producing or processing medical devices

- Plating and/or coating products

- Creatively transporting uniquely shaped products

Despite the extra output, our vertical conveyors do not require any extra floor space. Compact and efficient, they truly are a win-win for a company looking for a unique solution to increase profits, offset an investment of another type of equipment—or both.

Benefit 2: Cost-Effectiveness

Despite doubling output, operational costs to run a vertical conveyor are the same as traditional, horizontal conveyors. In fact, in some applications, costs are decreased with the vertical option, especially if multiple products are being transported at a time. (See Benefit 3.)

Benefit 3: Flexibility

A key benefit of vertical conveyor systems is their flexibility—but it’s two-fold.

- Vertical conveyors are able to transport more than one type of product at a time. This helps to reduce manpower needed on an assembly line to work on changeovers or reconfigurations on a shop floor.

- In addition, metal belts and conveyor systems have a high resistance to both chemical corrosion and extreme temperatures, making them appropriate for use across a wide variety of industries.

Benefit 4: Cleanliness

The medical and food industries are but two that benefit from vertical conveyors.

- Metal vertical conveyor systems are easy to clean and resistant to bacterial adhesion. This keeps medical tools and products hygienic and food products safe to consume.

- Likewise, with minimal touchpoints, medical or food products are less likely to accumulate debris, helping customers from both industries meet stringent safety standards.

- And because they do not require any lubricants, the medical or food items being transported are not susceptible to contamination.

You can hear more about the benefits a vertical conveyor offered one of our medical customers in this case study. Notably, the system has been running flawlessly since 1999 and contributed to the production of COVID-19 test kits during the height of the pandemic.

Benefit 5: Customization Options

No matter your industry or application, our experts can customize a vertical conveyor to suit your budget and meet your objectives. Choose from:

- Surface coatings and treatments to optimize product handling

- Custom perforations to aid in product tracking and transport

- Attachment integration

- And more

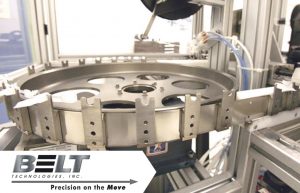

Building a vertical conveyor requires an innovative approach to engineering a solution. Our design experts give special attention to the relationship between the belt and its pulleys to guarantee the belt will not slip during normal operation. We’ve successfully developed methods to ensure belt alignment for numerous vertical systems and are prepared to assist with this important design element for your application. Ready to start designing? Contact us today.