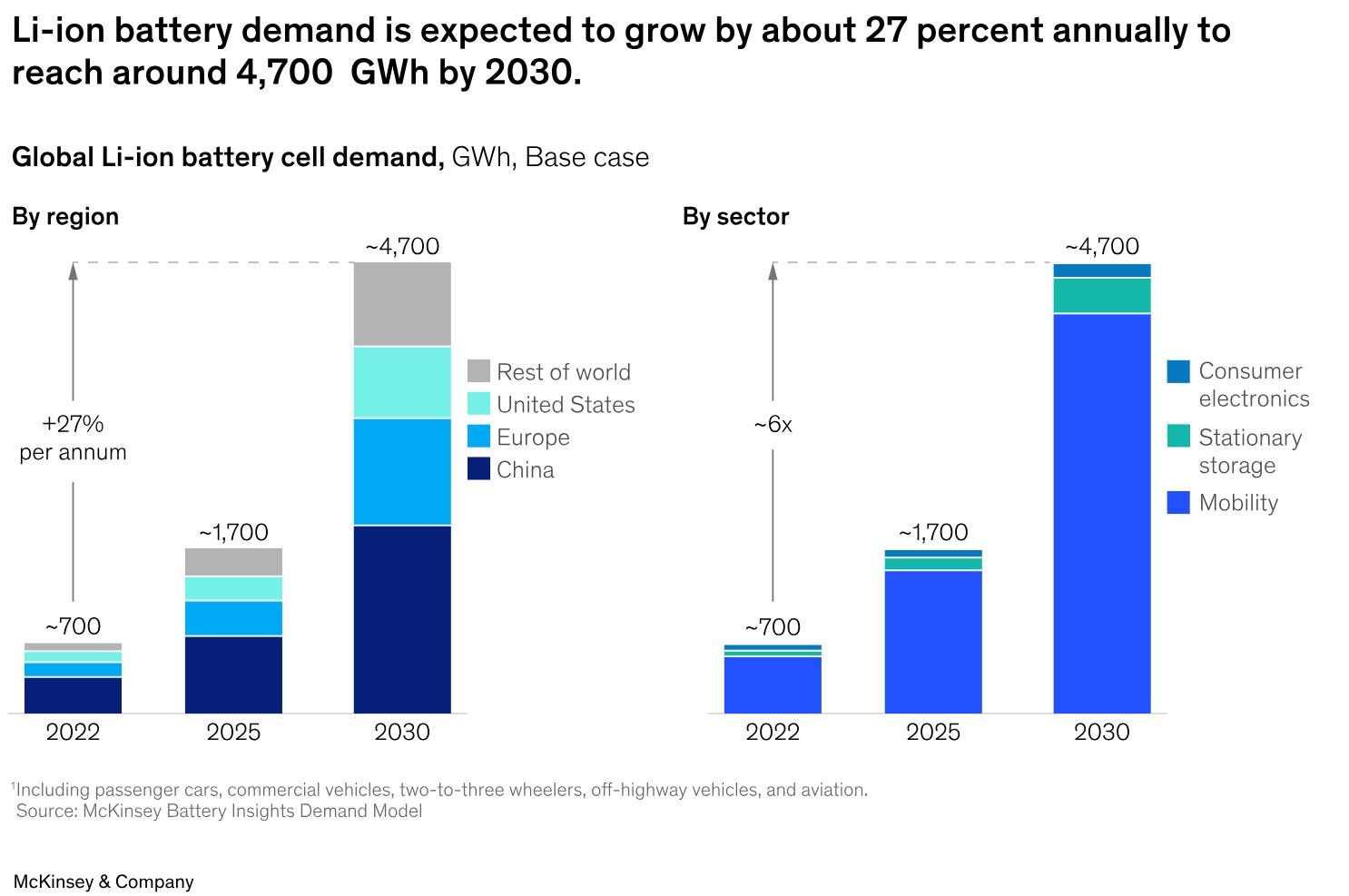

Within the next 5 to 6 years, experts anticipate demand for li-ion (lithium-ion) battery production to grow by at least 27% annually, thanks in large part to exponential growth in demand for electrical vehicles (EVs).1 Companies producing batteries are gearing up to meet that demand, examining every element of the production chain and identifying opportunities to enhance efficiencies. Precision, reliability and efficiency are paramount to producing safe, durable high-performance batteries—attributes our PureSteel® belts are designed to offer.

Rising to the Challenges of EV Battery Production

There are a number of challenges inherent to the production of batteries for EVs, which PureSteel® belts are designed to overcome. Here are some ways in which steel belts can help you be ready for the li-ion revolution:

Heavy Weights at High Volumes

EV battery production requires an assembly line to manage heavy, bulky materials at high volume. Steel conveyor belts provide reliable, durable support for these materials, helping to minimize breakdowns and interruptions. The strength and durability of PureSteel® belts reduces downtime and maintenance costs, ensuring a steady and reliable production flow.

Extreme Temperature

Essential to EV battery production are thermal management processes, including drying, curing and heat treatment. PureSteel® belts can withstand high temperatures and temperature fluctuations without deforming or losing integrity, ensuring more consistent and predictable battery component quality and minimizing belt-distortion-related production halts and safety hazards. We offer several alloys that operate at temperatures as high as 1,200°F.

Caustic, Corrosive Chemicals

The production of li-ion batteries involves exposure to a number of corrosive chemicals. Stainless steel conveyor belts are highly resistant to chemical corrosion, standing up to caustic chemical byproducts and cleaning solutions to ensure a more reliable, longer-lasting conveyor system.

Cleanliness and Hygiene Standards

It is imperative to maintain a meticulously clean production environment to prevent any impact on safety or battery performance resulting from contamination. The lack of any hidden gaps, recesses or crevices in our PureSteel® belts makes them far easier to clean and maintain, ensuring optimum hygiene.

Static Control

EV batteries contain sensitive electronic components that can be damaged by static electricity. The surface of a belt on a conveyor is continually rubbing against the pulley, creating friction and the potential for static electricity. Metal belts prevent static buildup and discharge static electricity, preventing damage to components.

Precision and Stability Requirements

Our metal belts and conveyor systems provide smooth movement, precise motion and positional accuracy—all absolute necessities when working in extreme environments to produce complex products with small, fragile parts. Stability and reliability also ensure optimum performance of the automated systems commonly used in modern battery production.

Recently, a battery-manufacturer required a high-precision solution for moving lithium material through their proprietary laser-cutting process. To meet the challenge, our team delivered matching pairs of timing belts, each featuring 5,000 welded attachments.

The Need for Adaptability and Futureproof Technology

EV battery designs can vary significantly between manufacturers. Metal belts can be customized to accommodate the full range of sizes, weights and production processes, offering complete flexibility to adapt to a range of specifications. As the industry continues to absorb technical advances in battery production, customizable steel belts can be adapted as needed, providing long-term utility.

PureSteel® is Pure Value

When comparing conveyor belt material options, manufacturers typically compare cost versus performance, benefits and longevity. While steel conveyor belts can have higher upfront costs versus alternatives, those costs are rapidly offset by the durability, stability and lower maintenance costs associated with steel, resulting in a considerable return on investment (ROI).

Steel belts provide essential advantages that result in considerable ROI:

-

Durability:

Reduced frequency of belt replacements minimizes halts in production. Steel belts’ resistance to heat and chemical damage results in a far greater lifespan.

-

Low Maintenance:

Reduced maintenance translates directly to lower operational costs and less downtime.

-

Quality Control:

Steel belts’ precision and stability help minimize defects and ensure consistent product quality.

-

Automation Compatibility:

Seamless integration with automated systems allows for smooth and efficient scaling of production.

-

Safety and Compliance:

Metal belts’ cleanliness and chemical resistance help manufacturers meet regulatory requirements and maintain certifications.

-

Environmental Considerations:

As the focus on sustainability continues to grow, many manufactures will consider the impact on the environment of production and disposal of conveyor belts. Metal belts require far less frequent replacement and are fully recyclable.

-

Supplier Reliability:

Belt Technologies is well established in the industry, with a proven track record of reliability and superior customer support. We offer the level of after-sales service, technical support and spare parts availability sought after by manufacturers across industries.

Stainless Steel Belts: The Future of Li-ion Battery Production

The future is powered by li-ion batteries, placing battery production at the front of the pack in growth industries. Battery manufacturers are in a position to prepare themselves for unprecedented growth and resulting rapid progression in production technologies.

Choosing steel belts for battery manufacture systems places your organization at an advantage, not only for immediate improvements in consistency and quality of product, but also for scalability and flexibility in adapting to advances and improvements in production capabilities

Are you a battery manufacturer interested in learning more about the benefit of PureSteel® belts? Reach out to us to discuss your project today!