Metal Conveyor Belt Pulleys and Pulley Configurations

Reduce Maintenance Downtime and Maximize Conveyor Lifespan

Metal conveyor belt pulleys are critical to the design of any automated conveyor belt system. They act as the driving force behind the motion of the belt, producing torque and speed. In very general terms it can be said that pulleys are categorized as friction drive or timing pulleys (type I and II). Precision is the name of the game when it comes to pulleys. A metal belt is only as good and precise as the pulleys. Most pulleys recommended by Belt Technologies are made of anodized aluminum (hard coat) with the right friction coefficient to drive the metal belt. Stainless steel can also be used but it is costly and heavy, although it might be indicated in certain applications where extra hardness is necessary. If your application requires a lighter pulley, the experts at Belt Technologies can help you select the best material.

Selecting the correct pulley size and configuration can have a significant effect on the lifespan and efficiency of a conveyor belt. Belt Technologies engineers have the knowledge and experience to help you choose the correct pulley type, diameter, and composition to minimize maintenance downtime and maximize product volume.

Metal Conveyor Belt Pulley Types

Belt Technologies designs custom metal conveyor belt pulleys and configurations to bring maximum efficiency to your system. While metal conveyor belts are typically made of stainless steel, pulleys can be produced from a variety of materials, including aluminum or a variety of plastic composites. Depending on the unique needs of your system, the pulleys can also be fitted with custom timing attachments, relief channels, and more.\

Our TruPulleysTM work to monitor or regulate the tension, pace or tracking of a metal belt. All TruPulleysTM are available as a standalone product or as part of a conveyor system designed by our engineers and are manufactured in the United States of America.

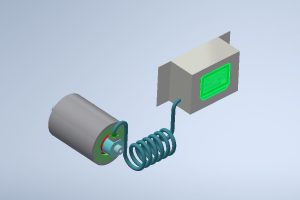

TruTensionTM Pulley

Belt Technologies has developed the TruTensionTM Pulley, a proprietary and state-of-the-art product unique to the belt conveyor market that precisely measures belt tension on conveyor systems.

TruPaceTM Pulley

Belt Technologies’ TruPaceTM Pulley brings reliability and synchronous operation to manufacturing or production floors. Compared to standard pulley designs of similar diameter and width, the TruPaceTM Pulley offers a significant decrease in inertia to allow designers to specify smaller motors and gearboxes for their equipment.

TruTrackTM Pulley

Belt Technologies’ patent pending TruTrackTM Pulley precisely automates belt tracking by using a frictionless segmented roller design with edge guides that also help to improve the lifespan of the belt.

Friction Drive Pulley

These pulleys are the standard pulley type for stainless steel conveyor belts. They are typically flat-faced and do not have timing elements, relying on the surface friction between the belt and pulley when the belt is properly tensioned. PureSteel® friction drive pulleys can also be designed with narrow bodies to make tracking easier and reduce overall weight and cost.

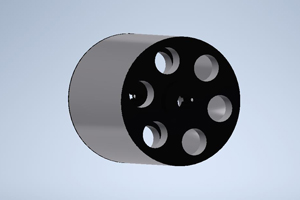

Timing Pulley

Timing pulleys are designed with teeth or pockets on the outside radius of the pulley body. These specially designed attachments engage with timing holes in the belt to achieve a synchronization of the belt and pulley. The timing mechanism also aids with straighter belt tracking and helps reduce the risk of any slippage in the belt.

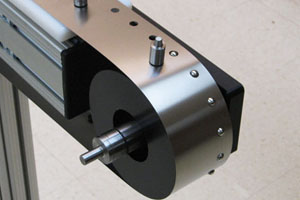

ISP (Independent Steerable Pulley)

The independently steerable pulley, typically the idler pulley, is designed to aid belt tracking by enabling the user to adjust the angle of the pulley relative to the belt and increase or decrease tension across its width. The PureSteel®ISP is exclusively available from Belt Technologies.

Custom Design and Engineering Services for Metal Conveyor Belts

Unlike conventional conveyor metal belts, the ratio between pulley diameter and belt thickness is critical to optimize the life of the belt. The configuration of the pulleys in the belt must also be considered. When designing a PureSteel® steel belt conveyor system, the number of bends (pulleys) should be minimized as well as maximizing the diameter of the pulley. Both factors optimize the life of the belt. Leave it to the experts at Belt Technologies to assess your application and help you choose the correct pulley type, diameter, and composition to minimize maintenance downtime and maximize product volume.

What can metal belt conveyor pulleys do for your automation system?