Design Considerations to Keep in Mind Before You Install

The most unexpected difference between metal belts and conventional conveyor belt types is the ratio between pulley diameter and belt thickness that must be maintained. While metal belts are typically made of stainless steel, pulleys can be manufactured from stainless steel, aluminum, or plastic, depending on the design specifications. Most metal belt pulleys are either round stock, I-beam, or capped tube and can be designed with drive lug timing pockets, relief channels, conventional timing teeth, or Belt Technologies’ patented ball bearing timing teeth. For metal belts to perform as well as they can, it is imperative to use the largest possible pulley diameter in relation to the thickness of the belt. The minimum ratio that we recommend at Belt Technologies is a strictly maintained 625:1.

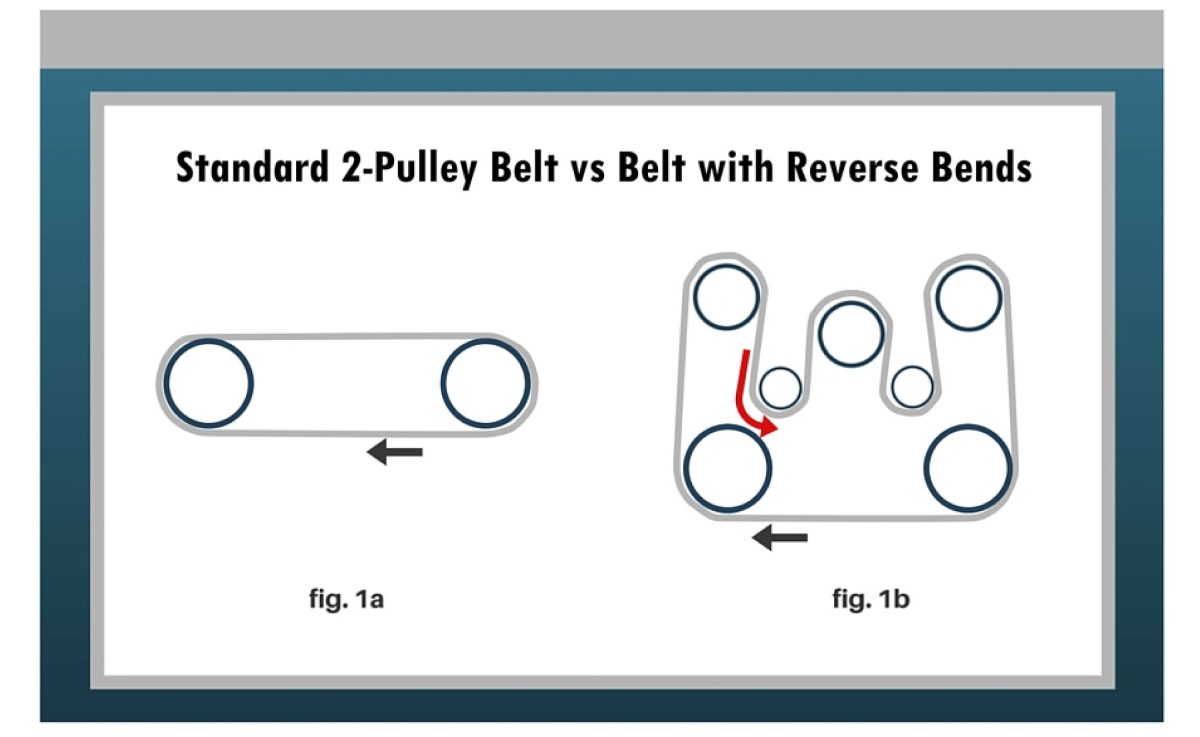

Reverse bends in metal belts should be avoided unless absolutely necessary, as they will compromise the lifespan of the belts. Along the same lines, there should be as few pulleys as possible included in the conveyor system to limit unnecessary stress on the belt.

Handle with Care

Although metal belts provide a higher resistance to temperature, chemical corrosion, and physical damage, they must be handled carefully during installation; particularly in the case of thinner metal belts. Damage can occur at the edges and at the weld joint of the belts during installation and maintenance.

The tension of the belt is another factor that can contribute to the lifespan of a belt. Belt tension should be kept as low as possible to improve belt life and reduce wear on the system. When tension is too high, the system frame can warp or the belt itself may fracture. Our engineers can help by providing guidelines to determine the right belt tension.

Keep It Clean

Metal belt conveyor systems should be designed with easy access to one side of the system. This reduces downtime during maintenance and sanitization procedures by making it easier to access the inner workings of the metal belt conveyor system. To prevent excessive damage to the belt, the interior and exterior diameter of the belt should be kept free of debris as much as possible.

By following these guidelines during the design phase of your metal belt conveyor system, you will maximize the lifespan of your stainless steel belt. Regular maintenance and proper cleaning should be part of your routine operations once the belt is installed. These measures will maximize the lifespan of the belt and reduce the chance of excessive damage from debris or misuse.