Every year on December 3 (3D) we celebrate 3D Printing Day. We hope we can convince you to join us in celebrating 3D Printing Day, too, by sharing some interesting things that have been 3D printed as well as some ways we have been fortunate to advance the industry.

What exactly is 3D printing?

To construct complex parts quickly and cost effectively, many manufacturers elect to use 3D printers, machines capable of producing three dimensional parts by way of additive manufacturing. This entails using a digital file to guide a machine to lay down successive layers of material, often plastic, to form a solid end product.

Infinite printing possibilities?

While the concept of 3D printing is still relatively new, a recent viral story helped it gain some mainstream understanding and acceptance. Earlier this year, Robert Downey, Jr. as Iron Man, delivered a 3D printed prosthetic arm to a grateful recipient. You can learn about his story here.

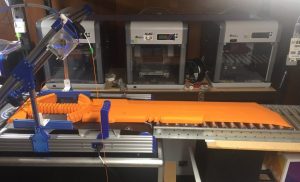

This touching story represents just one example of the infinite possibilities for 3D printing, including those produced by our customers. For instance, we helped one customer, a leading manufacturer of large scale industrial 3D printing equipment, to produce prototype designs for boat hulls, helicopter rotors and even a submarine nose cone. We also have the pleasure of working with a number of small independent 3D printers producing a myriad array of parts and even an 8-foot-long plastic sword. In each case, the mobility and precision provided by an endless stainless steel belt that can also stand up to the high heat generated by the printing process was critical to the performance of these machines.

How do we help?

We are regularly contacted by 3D printer OEMs to develop and fabricate parts of all shapes and sizes that aid in the 3D printing process. Why?

- Our stainless steel belts improve printing quality and accuracy during product production.

- Stainless steel has a high resistance to temperature extremes that can be achieved as printer heads move throughout applications and across sintering materials. Using our products means that production never has to slow down.

- Stainless steel is also highly durable and resistant to chemical corrosion and physical impact, other considerations of professionals involved in 3D printing.

- Our stainless steel belts, drive tapes and timing tapes provide a precisely movable base to print on. This allows for multiple items to be printed simultaneously, without operator action to remove completed printed parts from the machine, making our products a perfect addition to busy assembly lines.

- They also allow for the printing of larger parts: a section can be printed and then indexed by the belt to print the next section until the part is completed: our team can produce drive tapes as large as 35” for industrial-level equipment and as small as 0.1” for more specialty products and uses.

- Pulleys also play an essential part in performance and reliability by controlling belt systems and providing optimal belt tension and motion control.

Above all else, our products improve efficiencies and runtimes of 3D printing projects, helping to reduce labor expenses while increasing profit margins for companies large and small. Interested in learning more? Contact the experts at Belt Technologies for more information about our 3D printer drive tape, timing tape and pulley manufacturing capabilities.