by Belt Technologies | Aug 5, 2019 | Case Studies

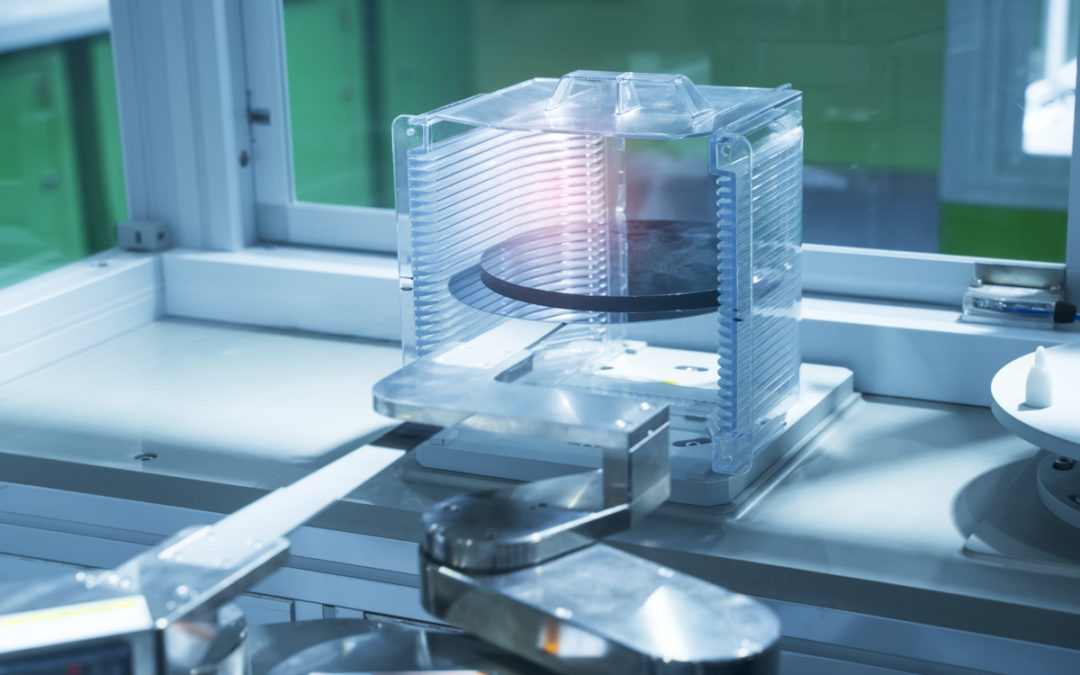

Recently, a longstanding customer of Belt Technologies approached us with a seemingly simple project. They needed replacement drive tapes for an existing robotic device. The customer specializes in developing and manufacturing advanced equipment used in the production...

by Belt Technologies | Jul 8, 2019 | Case Studies

At Belt Technologies, we specialize in providing expert solutions for unique industry applications. Recently, we were approached by an OEM producing automated robotic equipment for the dairy industry. The client came to the metal belt experts to troubleshoot an issue...

by Belt Technologies | Dec 18, 2018 | Case Studies

Belt Technologies has been working with OEMs specializing in the automated food processing industry for decades. Recently, a new food industry customer requested our help in designing and producing a stainless steel conveyor belt for a system designed to freeze...

by Belt Technologies | Sep 20, 2018 | Case Studies

Belt Technologies was recently approached by a customer that produces plastic pellets for recreational and automotive components. The pellets were made by extruding hot, melted plastic onto a conveyor belt which would then be transported to the next production phase...

by Belt Technologies | May 17, 2018 | Case Studies

Belt Technologies has the capability to produce custom stainless steel belts for a variety of unique applications beyond conveyor belt systems. One such application includes an automated pill dispenser cabinet for a large, medical device OEM. The dispenser for these...

by Belt Technologies | Mar 27, 2018 | Case Studies

A stainless steel belt is considered “wide” when it is between 22 to 35 inches in width. Wide belts require particular consideration to produce and are traditionally made with thicknesses of 1 millimeter or greater to preserve belt integrity. At Belt Technologies, one...