by Belt Technologies | Nov 18, 2016 | Blog

Belt tracking refers to the methods used to keep a conveyor belt properly aligned and centered during linear motion. A belt tracking left or right is gradually moving in that direction. Conveyor belts must be centered on their tracks to achieve accurate and repeatable...

by Belt Technologies | Sep 30, 2016 | Blog

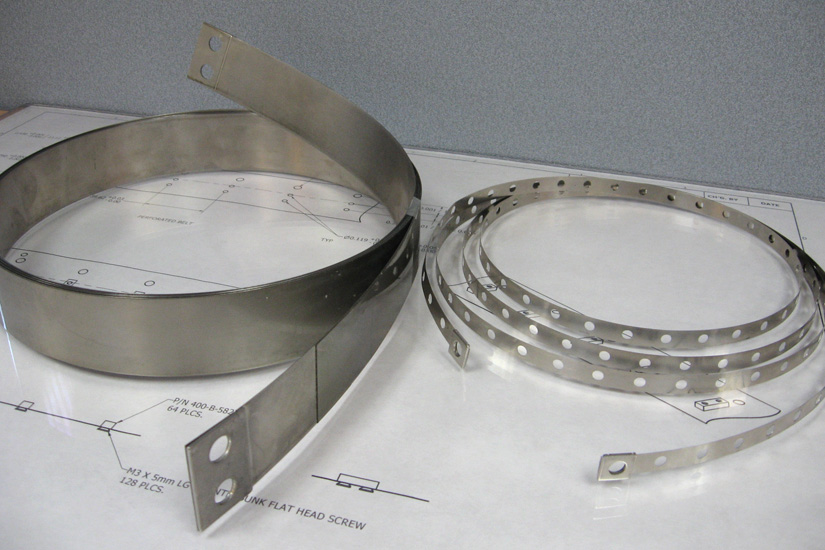

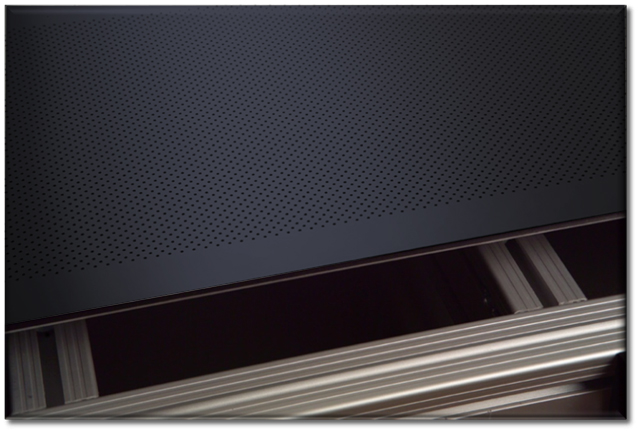

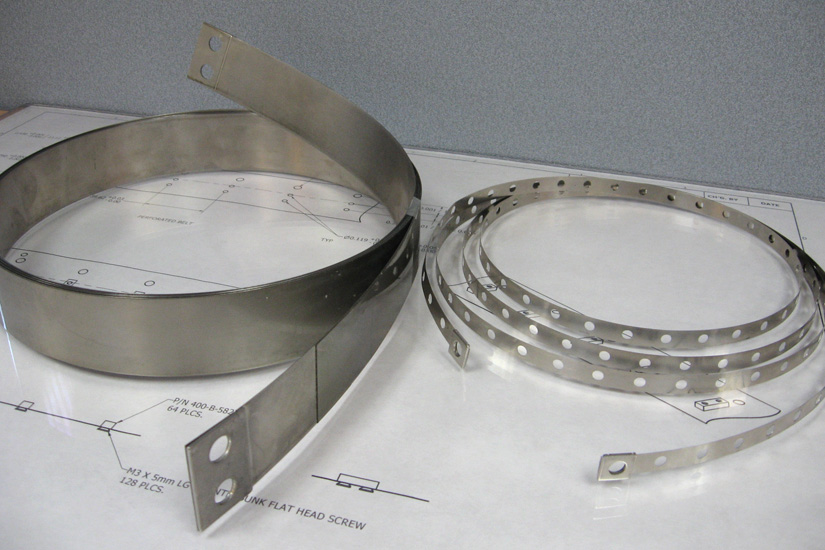

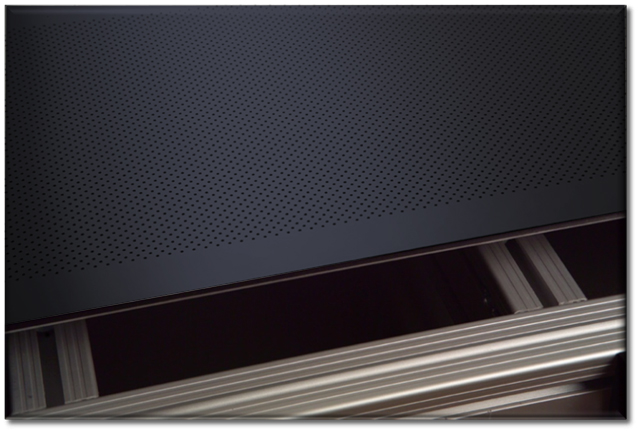

Since early 2016, Belt Technologies, Inc. has expanded our in-house capabilities to include custom laser cutting and perforation services. The laser cutting and custom laser-cut perforation patterns of metal conveyor belts, timing belts, and drive tapes can now be...

by Belt Technologies | Sep 29, 2016 | Blog

Belt Technologies is building up its global presence by connecting with customers in emerging, worldwide technological markets. A major initiative of this strategy is to meet with global partners and industry leaders at international trade shows; this helps raise...

by Belt Technologies | Aug 26, 2016 | Blog

The pharmaceutical market is highly competitive and requires pharmaceutical OEMs to produce equipment that guarantees quality and safety while maintaining high efficiency and low production costs. Customers demand pharmaceutical processing equipment that is fast,...

by Belt Technologies | Aug 5, 2016 | Blog, The Headline News, Uncategorized

A major OEM in the metrology and precision optical instrumentation industry recently approached Belt Technologies seeking drive tapes for its new line of coordinate measuring machines (CMMs). The company has been incorporating stainless steel drive tapes into their...

by Belt Technologies | Jun 30, 2016 | Blog

Coatings and surface treatment applications can enhance conveyor system functionality and performance by altering the surface properties of the conveyor belt. There are many options for coating and surface treatments, including GATORCOATⓇ, neoprene rubber, and hard...