by Belt Technologies | Dec 18, 2018 | Case Studies

Belt Technologies has been working with OEMs specializing in the automated food processing industry for decades. Recently, a new food industry customer requested our help in designing and producing a stainless steel conveyor belt for a system designed to freeze...

by Belt Technologies | Nov 28, 2018 | Available Positions

Applications Engineer Responsibilities: Produce engineering drawings and BOM specifications based on customer and product design requirements. Work directly with sales and the customer to develop steel belt specifications Design and specify tooling used in the...

by Belt Technologies | Sep 20, 2018 | Case Studies

Belt Technologies was recently approached by a customer that produces plastic pellets for recreational and automotive components. The pellets were made by extruding hot, melted plastic onto a conveyor belt which would then be transported to the next production phase...

by Belt Technologies | Aug 23, 2018 | Video Tutorials

Proper belt installation and removal safeguards automated conveyor systems against accidental damage, enables accurate belt tracking, and helps to extend the life of the belt by reducing unnecessary wear or friction. This step-by-step tutorial will demonstrate the...

by Belt Technologies | Jun 5, 2018 | Blog

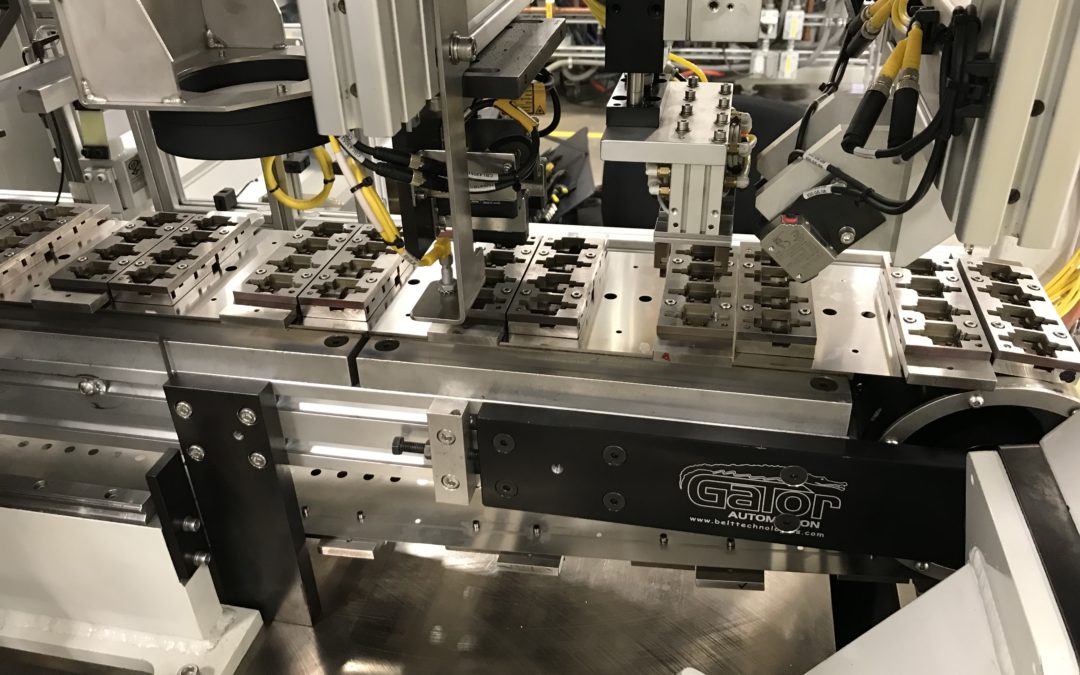

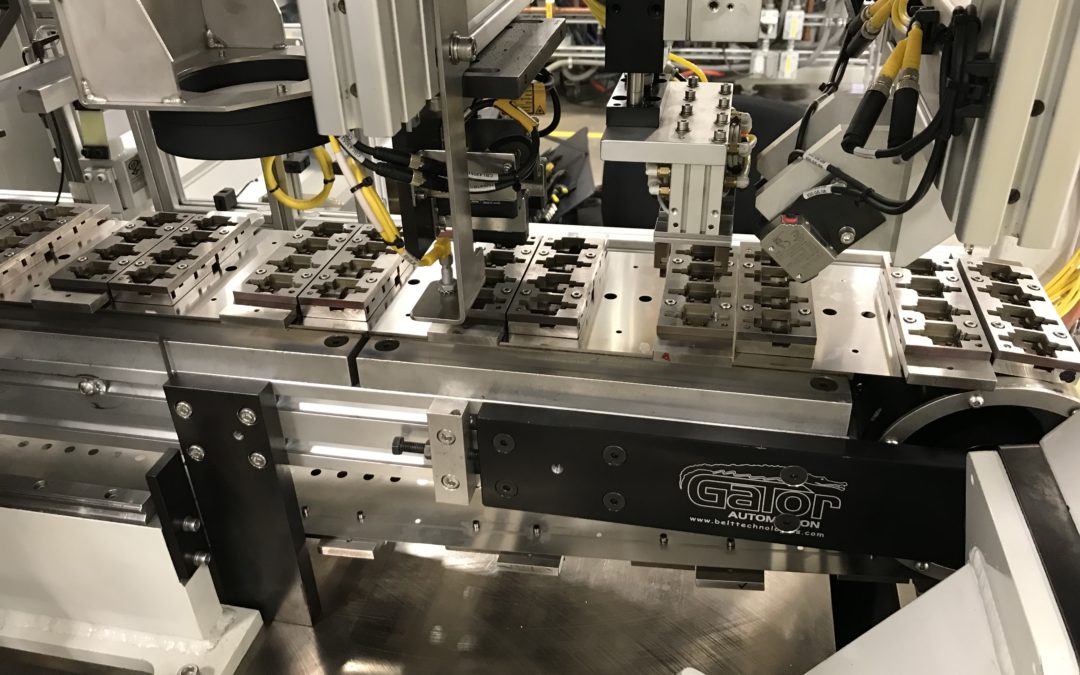

Recently, a customer from a previous project contacted Belt Technologies with a problem. Our engineers had provided them with a conveyor belt for the production of electrical connectors. Unfortunately, they were experiencing issues with the belt after it was installed...